Quality, traceability, and processability

Valsir Recycling has the technology required to transform any polyolefin plastic waste into End of Waste material in regrind or pellet form: our thirty years of experience in the transformation of plastic materials allows us to offer and guarantee End of Waste materials of high quality made from recycled polypropylene and polyethylene.

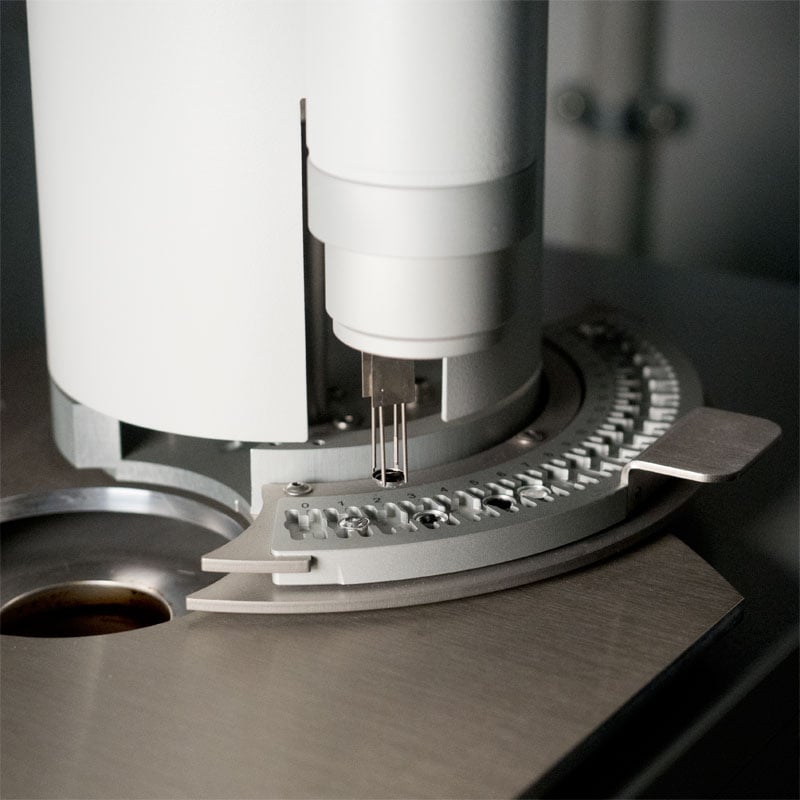

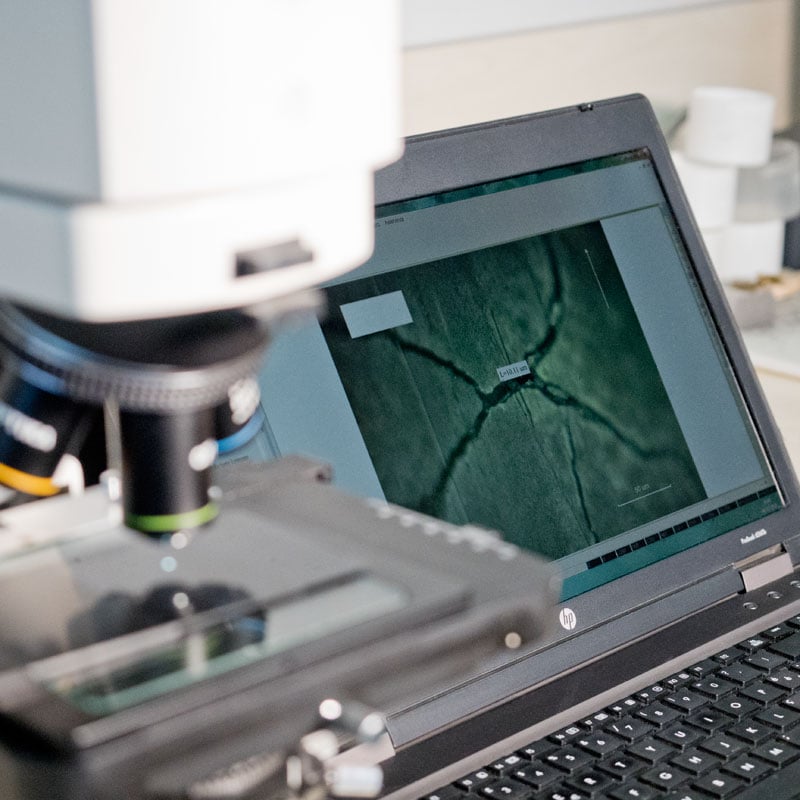

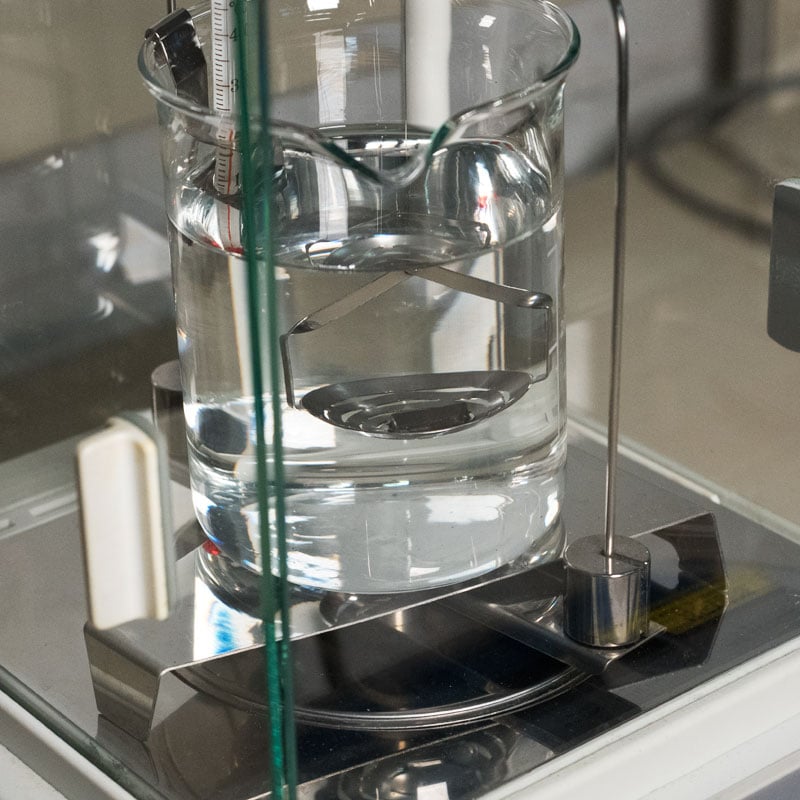

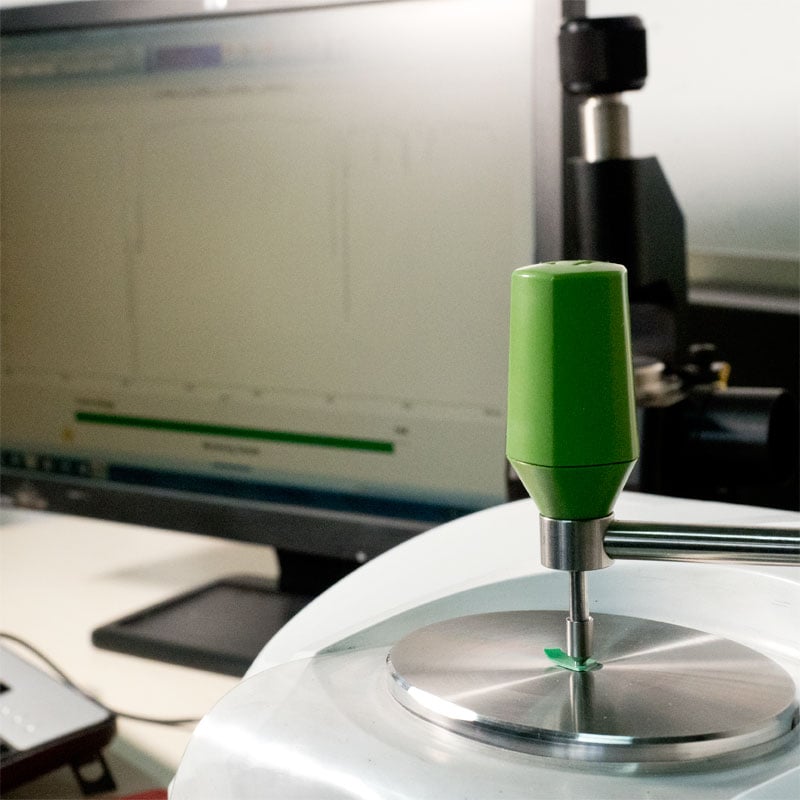

Thanks to our internal laboratory, we’re able to monitor the quality of our products throughout each stage of their production process, guaranteeing full compliance with the Uniplast 10667 standards and complete traceability.

Our challenge is to provide high-quality compounds while at the same time ensuring excellent performance in terms of processability, mechanical performance, aesthetics and respect for the environment.

Our plastic processing expertise also allows us to develop compound solutions specifically designed to meet each customer’s needs.

In order to effectively meet the need to reuse polyolefin-based plastic waste materials that are difficult to recycle mechanically, we’ve expanded our activities by investing in the new pallet department.

This allows us to help our customers and suppliers bring their circular economies full circle by transforming their plastic waste into high-capacity pallets made from 100% recycled plastic, which can be made with custom colours, personalised logos, and various other options.

Thanks to our laboratory technologies and R&D activities, we’ve managed to develop and create compounds that perfectly meet our customers’ chemical-physical, mechanical and aesthetic requirements.